PR115S / PR120S

Next Generation PVD Grades for Heat-Resistant Alloy

Download Brochure Exclusive Kit Offers!NEXT GENERATION PVD TECHNOLOGY

Conquer challenges of turning heat-resistant alloys with Kyocera's PR115S / PR120S Series

Long Lasting Efficiency

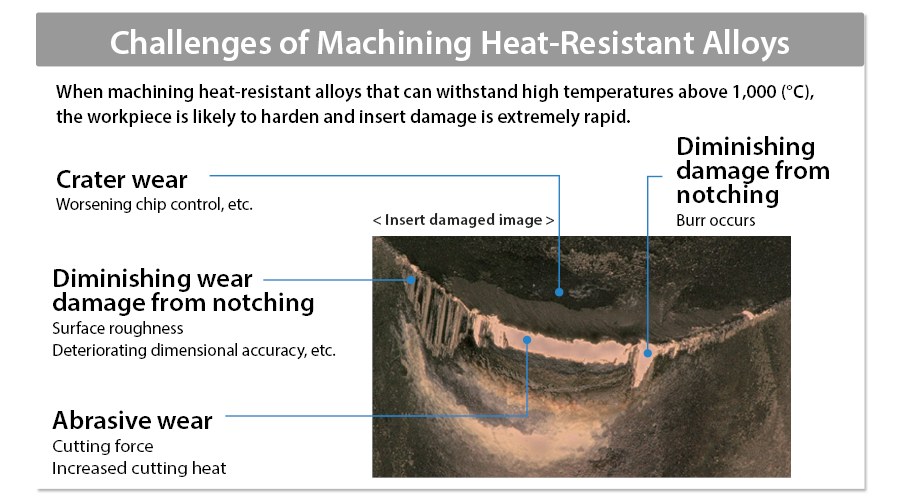

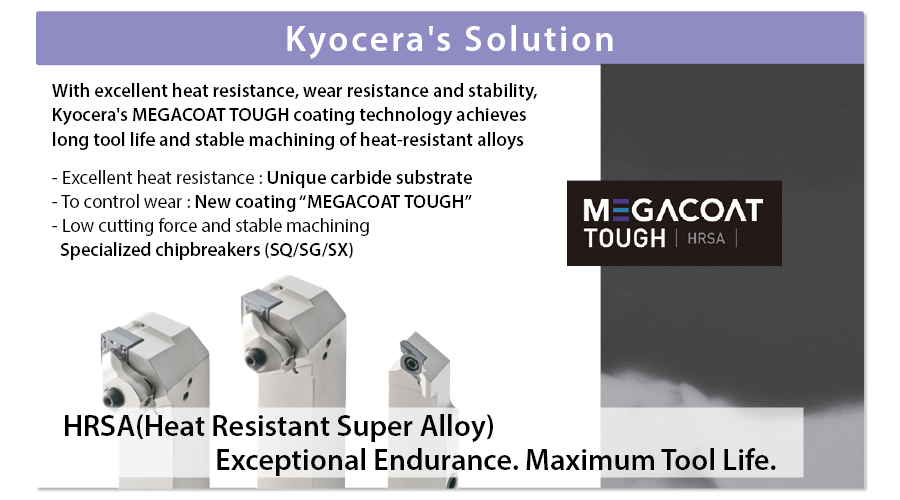

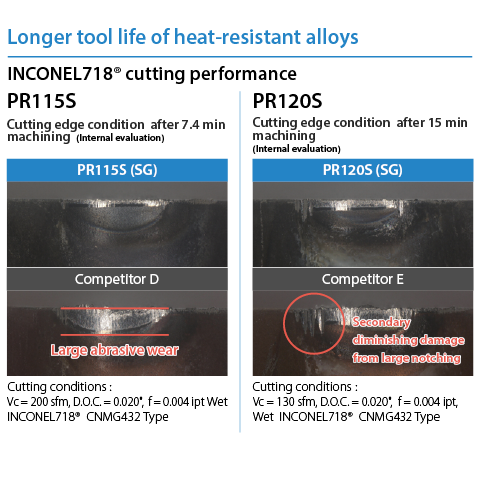

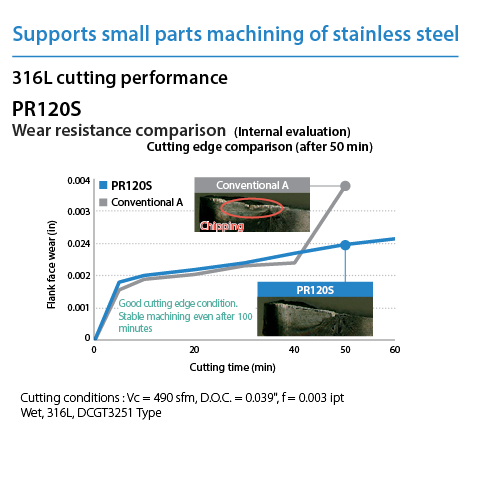

Machining heat-resistant alloys and stainless steel can present numerous challenges, including rapid insert degradation, deterioration of dimensional accuracy, poor chip control, burrs, increased cutting forces, and excessive heat generation. Kyocera is excited to unveil the PR115S/PR120S series, a comprehensive solution designed to tackle these challenges head-on. With outstanding heat resistance, wear resistance, and stability, this series ensures prolonged tool life and enables stable machining results in both heat-resistant alloys and stainless steel.

Under the Surface

The PR115S/PR120S series features the MEGACOAT TOUGH HRSA coating, offering exceptional endurance and maximum tool life for machining heat-resistant super alloys (HRSA). The inserts consist of four distinct layers. The first layer utilizes thick-film PVD coating technology, suppressing abrasive wear, and reducing notch damage with its ultra-fine grain structure. The second layer, a TiAlN coating, provides superior oxidation resistance and controls crater wear. The third layer serves as an adhesion layer between the carbide substrate and the main coating layers, enhancing adhesion and scratch resistance. The fourth layer is a unique carbide substrate, formulated specifically for heat-resistant alloy machining, with excellent thermal properties and high thermal conductivity. The PR115S employs a mixed structure of fine and coarse grain carbide for improved heat and wear resistance, while the PR120S utilizes a coarser grain structure for heat resistance and more stability.

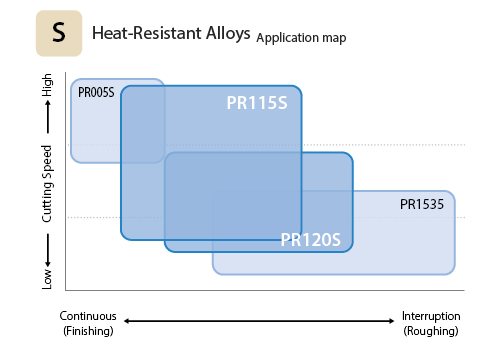

Wider application range for greater versatility

Excellent wear and heat resistance

PR115S

Covers a wide range of difficult-to-cut machining applications

1st recommendation for continuous finishing of heat-resistant alloys

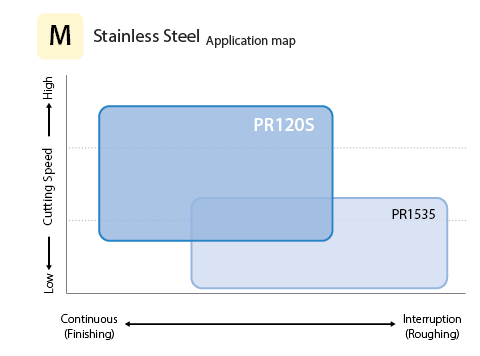

PR120S

Long tool life and stable machining in interrupted machining of heat-resistant alloys

1st recommendation for continuous finishing to light interrupted machining of stainless steel

Longer tool life extension possible for stainless steel machining

Maximizing tool life with newer coating advancements

Unique carbide substrate with excellent heat resistance and new coating "MEGACOAT TOUGH"

2x tool life in HRSA and Stainless Steel

Excellent wear and abrasion resistance in HRSAs and also supports stainless steel small parts machining

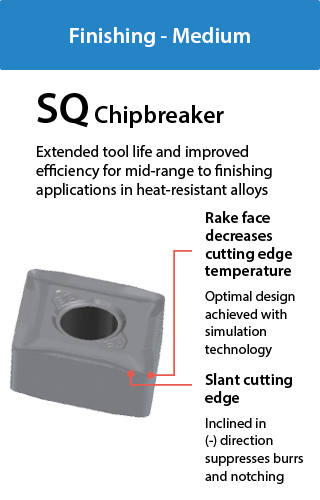

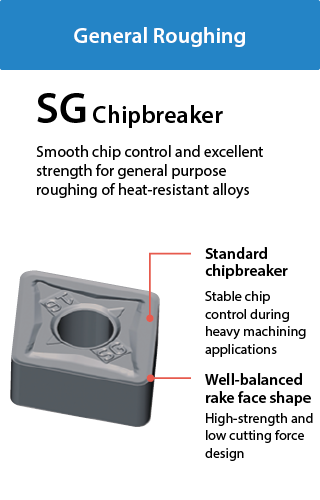

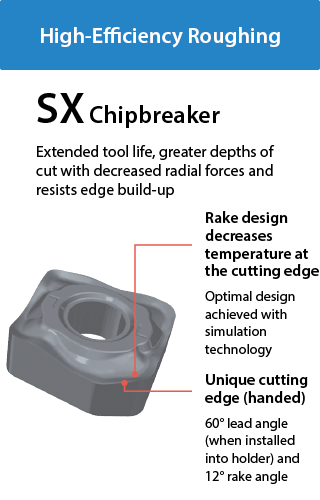

Specialized chipbreakers designed for HRSAs

New chipbreaker designs (SQ/SG/SX) improve machining stability

Case Studies

Ready to make a purchase?

Kyocera Precision Tools are sold through authorized distributors throughout North America

Contact a distributor nearest you below

Tell 'em we sent you...

© KYOCERA Precision Tools | All rights reserved.

© KYOCERA Precision Tools | All rights reserved.