PR1725 / PR1705

PVD Coating for Small Parts Machining

Download Brochure Locate DistributorHIGH-PRECISION MACHINING

for General Steel, Free-Cutting Steel, and Stainless Steel

Newly developed PVD grade using MEGACOAT NANO PLUS coating technology for exceptional surface finish and long tool life

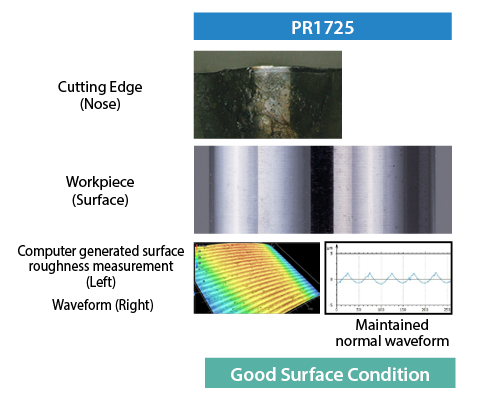

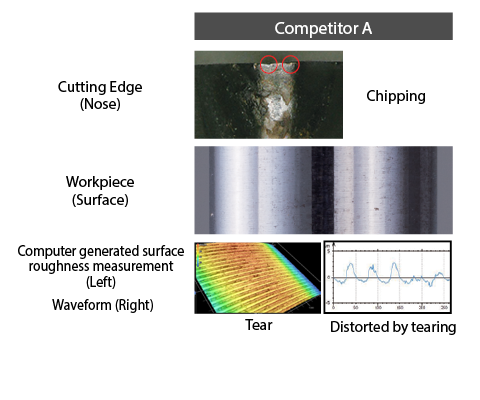

PR1725 Maintains Long Tool Life and Excellent Surface Finish

Long tool life leads to improved cycle time

Excellent surface finish with no tearing lowers quality control costs

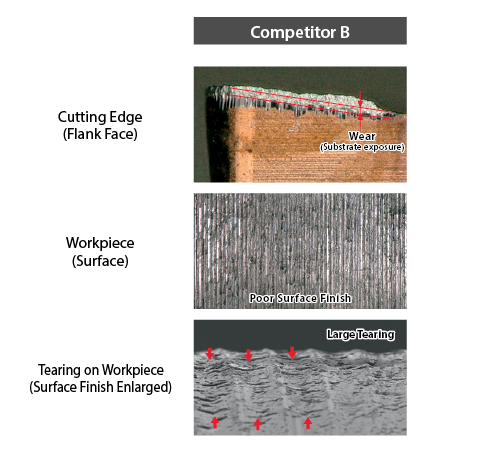

Insert cutting edge wear and quality of surface finish comparison (1045 Steel)

* After 20 min of machining (Internal evaluation)

Cutting Conditions : Vc = 490 sfm, D.O.C. = 0.020", f = 0.002 ipr, Wet, Workpiece : 1045

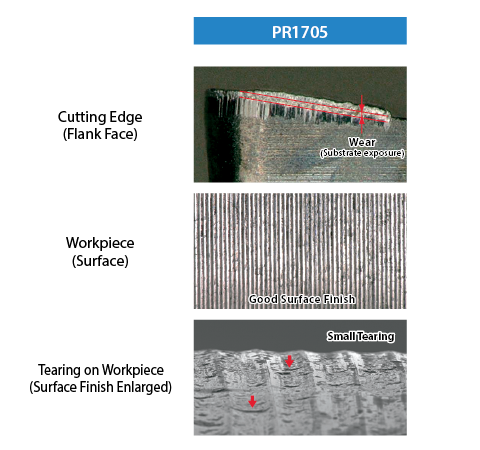

PR1705 Excellent Wear Resistance and High-Precision Machining

High-hardness ultra-fine particle carbide substrates with MEGACOAT NANO PLUS coating technology

Insert Wear and Surface Finish Comparison (1215 Free-Cutting Steel)

* After 40 min of machining (Internal evaluation)

PR1705 showed little adhesion to the cutting edge and good surface finish on the workpiece without tearing

Cutting Conditions : Vc = 490 sfm, D.O.C. = 0.0197", f = 0.0020 ipr, Wet, Workpiece : 1215

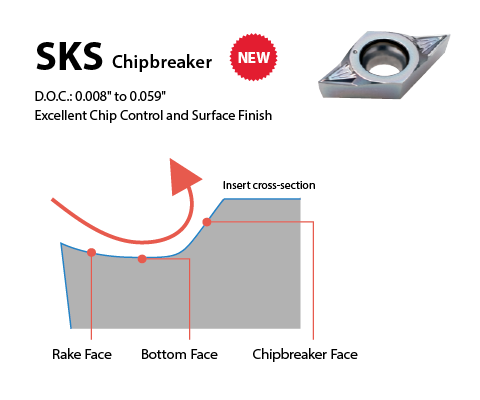

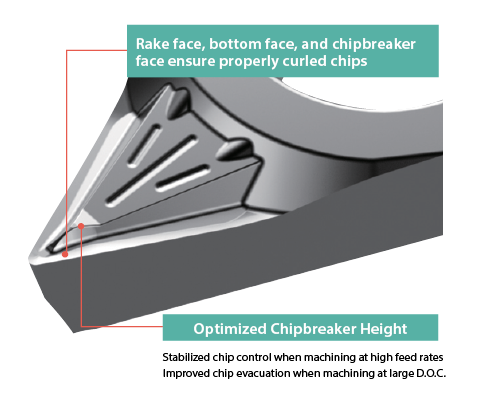

New SKS Chipbreaker Design for Finishing

Anti-welding properties for improved mirror surface finish and excellent chip control

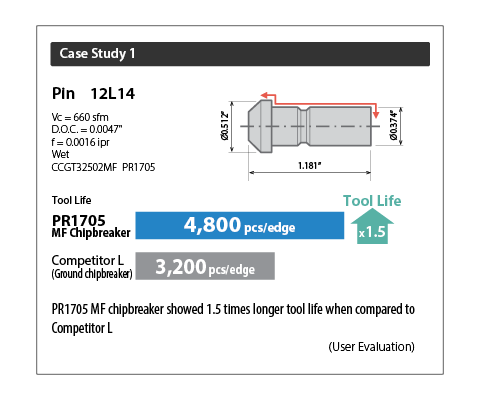

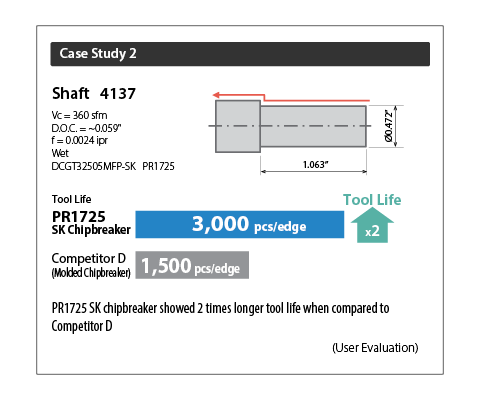

Case Studies

Ready to make a purchase?

Kyocera Precision Tools are sold through authorized distributors throughout North America

Contact a distributor nearest you below

Tell 'em we sent you...

© KYOCERA Precision Tools | All rights reserved.

© KYOCERA Precision Tools | All rights reserved.