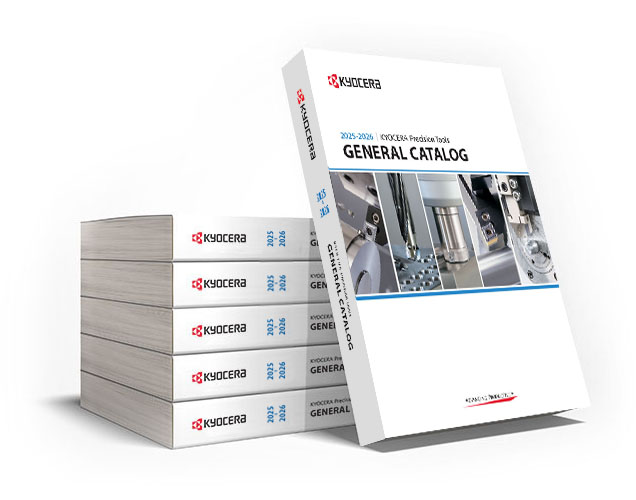

NEW 2025-2026 Indexable Cutting Tool Catalog!

Including indexable turning, milling, grooving & cut-off, threading and drilling solutions

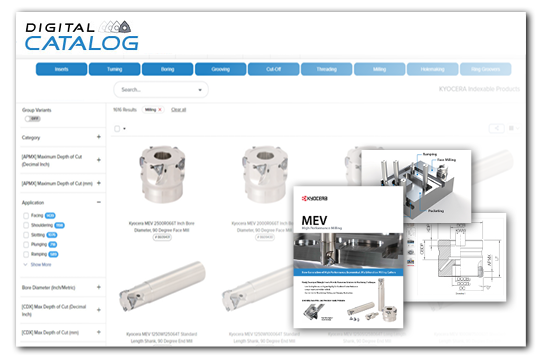

Try our online digital catalog!

- The most up-to-date product information available

- Full indexable cutting tool product lineup

- Quickly search part numbers, descriptions, and features

- Extensive product dimensions and usage information

- Downloadable images, drawings, literature, and CAD files

- Customizable filters for faster product navigation

- Side-by-side product comparison features

Featured 2025-2026 Catalog Updates

MB45 General Purpose 45° Milling Series

The MB45 Milling Series setting a new standard for general purpose milling featuring economical 8-edge inserts and an innovative new helical body design giving customers a more durable and versatile cutter with better finish capabilities over conventional mills.

View product page › View product brochure ›MA90 Multi-Functional 90° Milling Series with Tangential Inserts

The MA90 Milling Series featuring 4-edge tangentially mounted inserts, ensures ultimate body rigidity, superior chip evacuation, enhanced tool life, and impeccable surface finishes.

View product page › View product brochure ›KGZ Precision Cut-Off and Grooving Solutions for Small Parts

The KGZ series cut-off and grooving system is a cutting-edge solution designed specifically for the challenges of small parts machining with enhanced stability, efficiency, and repeatability.

View product page › View product brochure ›KAV Anti-Vibration Boring Bar Series

The KAV Boring Bar Series, a revolutionary solution designed to tackle challenging deep-boring tasks with unparalleled efficiency. This new series showcases Kyocera's commitment to innovation, featuring advanced anti-vibration dampening technology and replaceable heads for optimal deep boring performance.

View product page › View product brochure ›CA115P / CA125P CVD Insert Grades for Steel

These next-gen CVD grades combine an innovative coating, carbide substrate, and chip breakers to deliver exceptional performance, wear, and fracture resistance. The CA115P/CA125P series revolutionizes steel machining with remarkable endurance and longevity.

View product page › View product brochure ›PR115S / PR120S PVD Grades for Heat-Resistance Alloys

The PR115S/PR120S series features Kyocera’s new MEGACOAT TOUGH HRSA proprietary coating technology, offering exceptional endurance and maximum tool life for machining heat-resistant super alloys (HRSA). The inserts consist of four distinct layers.

View product page › View product brochure ›PR18 Series Next-Generation Milling Grades

With PR18 Series inserts, machinists can eliminate frequent tool replacements and costly downtime, as Kyocera’s cutting-edge coating brings an unmatched level of longevity to milling operations in a large variety of workpiece materials.

View product page › View product brochure ›KBN010 / KBN020 CBN Insert Grades for Hardened Materials

KBN020, excels as a 1st choice for general purpose continuous to heavily interrupted machining. The KBN010 grade expansion is specialized for high-speed finishing. The unique, mixed structure of micro grain and coarse grain CBN provides greater wear resistance and optimal surface finish at higher speeds compared to KBN020.

View product page › View product brochure ›

© KYOCERA Precision Tools | All rights reserved.

© KYOCERA Precision Tools | All rights reserved.